charpy impact test standards|charpy impact test sample dimensions : wholesalers ISO 148-1:2016 specifies the Charpy (V-notch and U-notch) pendulum impact test method for determining the energy absorbed in an impact test of metallic materials. This part of ISO 148 . Corowa /ˈkɒrəwə/ is a town in located in the Murray region in the state of New South Wales in Australia. It is on the bank of the Murray River, the border between New South Wales and Victoria, opposite the Victorian town of Wahgunyah. It is the largest town in the Federation Council and was the administrative centre of the former Corowa Shire. The name could have derive.

{plog:ftitle_list}

Resultado da Dragão Corrompido. Não se aproxime demais deste aqui ou vai acabar levando uma vaia. Ele tem uma personalidade maligna e um comportamento destrutivo. Para ele, todo mundo é um duende e rasteja misteriosamente por Dragon City. A única coisa que consegue acalmá-lo é peixe fresco. Anúncio.

Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its .In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture. Absorbed energy is a measure of the material's notch toughness. It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and cheaply. A disa.

4.5 The Charpy V-notch impact test as a powerful tool for delivery control in steel specificationsStandards. • ASTM E23: Test Methods for Notched Bar Impact Testing of Metallic Materials. Purpose. • To determine the energy required to fracture a v-notched specimen. This energy .ISO 148-1:2016 specifies the Charpy (V-notch and U-notch) pendulum impact test method for determining the energy absorbed in an impact test of metallic materials. This part of ISO 148 .ISO 179-1:2010 specifies a method for determining the Charpy impact strength of plastics under defined conditions. A number of different types of specimen and test configurations are .

The Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test that determines the amount of energy absorbed by a material during fracture. This . 1.1 These test methods describe notched-bar impact testing of metallic materials by the Charpy (simple-beam) test and the Izod (cantilever-beam) test. They give the .The Charpy test is a standardized procedure designed to measure the energy absorbed by a material during a sudden impact load. This evaluation method assesses the material's .

Standards • ASTM E23: Test Methods for Notched Bar Impact Testing of Metallic Materials Purpose . translates into the toughness of the material. Equipment and Materials • Charpy V-notch impact testing machine (figure 1.3.1) • Specimens: 1018 CR steel & 6061-T6 aluminum • Thermometer • Water • Dry ice • Hot plate • Oven .4.5 The Charpy V-notch impact test as a powerful tool for delivery control in steel specifications. 5 Information to be gained from the impact test. . ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies (ISO member bodies). The work of preparing International Standards is normally .Charpy Impact Test ISO 179. Charpy Impact is a single point test that measures a materials resistance to impact from a swinging pendulum. Charpy impact is defined as the kinetic energy needed to initiate fracture and .

charpy test sample dimensions

1.1 These test methods describe notched-bar impact testing of metallic materials by the Charpy (simple-beam) test and the Izod (cantilever-beam) test. They give the requirements for: test specimens, test procedures, test reports, test machines (see Annex A1) verifying Charpy impact machines (see Annex A2), optional test specimen configurations . A Charpy test determines the impact toughness of metal samples by striking them with a swinging mass. The traditional test method requires measuring the difference between the height of the striker before and after impact. . But all of them still need to be verified periodically using standards issued by organizations such as the American .

CHARPY IMPACT TEST ISO 179 Charpy Impact is a single point test that measures a materials resistance to impact from a swinging pendulum. Charpy impact is defined as the kinetic energy needed to initiate fracture and continue the fracture until the specimen is broken. The values recorded can be used for quality

For a comprehensive solution to test impact toughness in metals, our Charpy Impact Tester for Metals is designed to meet ASTM E23 standards, ensuring high-quality and reliable results. If your focus is on plastics or polymers, the Charpy Izod Pendulum Impact Tester for Plastics is perfect for assessing the toughness of non-metal materials.

Engineers and researchers who have specialized Charpy testing needs will be the primary users of two new standards recently approved by ASTM International Committee E28 on Mechanical Testing. The new standards, E2248, Test Method for Impact Testing of Miniaturized Charpy V-Notch Specimens, and E2298, Test Method for Instrumented Impact Testing of Metallic .

Charpy Impact is a single point test that measures a materials resistance to impact from a swinging pendulum. Charpy impact is defined as the kinetic energy needed to initiate fracture and continue the fracture until the specimen is broken. The values obtained can be used for quality control or to differentiate general toughness. Test Procedure: Charpy impact test standards. ASTM E23, ASTM D6110, ASTM A370, ASTM D256. ISO 13479, ISO 148-1. EN 10045-1, EN ISO 179-1 Izod impact testing. While Charpy impact testing is widespread for metals, Izod impact testing is more often used for plastics and other softer materials. In Izod testing, the notched specimen is positioned vertically instead . A Charpy impact testing apparatus, a device with a pendulum with various locking points at specified heights and a fixture to hold the test specimen, is used to determine Charpy impact strength. . ASTM D256 / ISO 180: These standards govern impact testing for plastics. ASTM A370 / ASTM E208: This standard governs impact testing for steel .

The standards ISO 179-1 (non-instrumented impact strength test) and ISO 179-2 (instrumented impact strength test) describe the Charpy impact test for determination of the impact characteristics (impact strength and notched impact strength) of plastics. Impact tests to Charpy are also described in the ASTM D6110 standard.For an explanation on the voluntary nature of standards, the meaning of ISO specific terms and expressions related to conformity assessment, as well as information about ISO's adherence to the . ISO 13802:2015, Plastics — Verification of pendulum impact-testing machines — Charpy, Izod and tensile impact-testing 3 Terms and definitionsCharpy impact testing is a low-cost and reliable test method for measuring the impact resistance of materials and is commonly required by construction codes for fracture-critical structures and pressure vessels. In its most common form (notched specimen . the U.S. infrastructure up to safe standards.

There are ISO product, method, and instrument standards for impact tests with pendulum impact testers. . which has also earned these machines the designation of Charpy impact testers or Charpy impact testing machines. . Abstract. This paper is focused on the approximation of absorbed Charpy impact energy-temperature curves (KV-T) and the management of sub-size test piece results in Charpy pendulum impact tests. Both subjects are frequently underestimated but may have a strong impact on the assessment of product quality and structural integrity. The status of related test .Both methods characterize the impact strength of a material in very similar ways so that the results largely correlate. The Izod test method, in which the specimen is positioned vertically, is normally used in ASTM standards.; The Charpy .

The Charpy impact test is still used throughout sectors to assess material toughness, from construction and manufacturing to engineering and beyond. This test offers practical insights into how materials respond to sudden, dynamic impacts. Even as businesses change, the Charpy impact test is still a valuable and essential tool.Charpy to ISO 179-1 is the preferred test method on plastics within the standard for single-point data ISO 10350-1. The test is ideally performed on unnotched specimens with edgewise impact (1eU). Should the specimen not break during the test, any subsequent tests are performed with notched specimens. Similarly, the Charpy impact test is governed by standards such as ASTM E23 and ISO 148. These standards provide guidelines for the preparation of notched specimens, the pendulum's energy, and the testing environment. The results are also expressed in joules or foot-pounds, providing valuable data on the material's toughness and impact .

Compatible with the full range of CEAST impact testing systems, including pendulum type machines (CEAST 9000 Series) and drop towers (CEAST 9300 Series), it’s the key for instrumented impact testing. The DAS 64K also enables the data collection from instrumented tups or hammers on older models and non-CEAST impact machines. 1.1 These test methods describe notched-bar impact testing of metallic materials by the Charpy (simple-beam) test and the Izod (cantilever-beam) test. They give the requirements for: test specimens, test procedures, test reports, test machines (see Annex A1) verifying Charpy impact machines (see Annex A2), optional test specimen configurations .

Element provides the Charpy impact test services in accordance with multiple International standards such as NADCAP, ISO 148, and ASTM E23 for both metallic and polymeric materials. Guarantee End-User Safety and Elevate Quality Control: In safety-critical applications like construction or transportation, our testing ensures your materials .Test Standards of Charpy Impact Tests: JIS K 7111-1, ISO 179-1, ASTM D 6110. In a Charpy impact test, the test sample is supported at both ends. The hammer strikes the center of the sample on the side opposite of the notch. The sample is set simply by placing it on the anvil (test station) and therefore tests can be performed easily and .

According to current Charpy test standards (ASTM E23-12c and ISO 148-1:2009), absorbed energy (KV) results from partially fractured test specimens can be averaged with the results from fully fractured specimens. However, most researchers agree that if a specimen does not fully fracture at the end of a Charpy test, a significant

charpy impact test standard pdf

The Charpy impact test, also commonly referred to as the Charpy V-notch test by material scientists, serves as a standardized high-strain rate examination to quantify the energy absorbed by a material upon fracture. The absorbed energy functions as an indicator of the material’s notch toughness.

The resulting test sample measures 80 x 10 x 4 mm. The depth under the notch of the specimen is 8mm. Data: ASTM impact energy is expressed in J/m or ft-lb/in. Impact strength is calculated by dividing impact energy in J (or ft-lb) by the thickness of the specimen. The test result is typically the average of 5 specimens.

types of hardness testing machine

types of hardness testing methods pdf

types of hardness tests

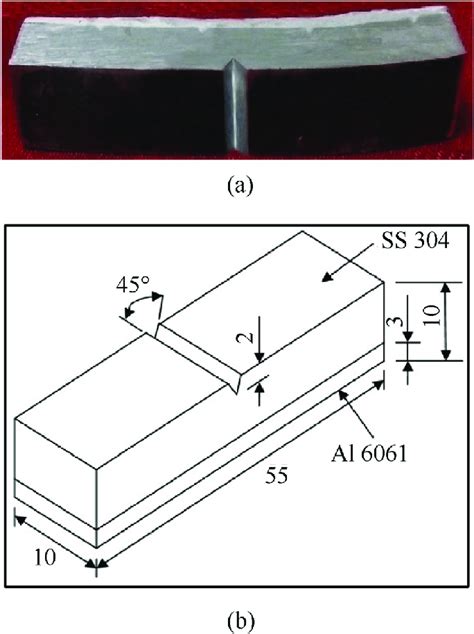

charpy impact test specimen size

WEBHoje Alottoni, Bluehand, Atila, André Souza, Fábio Yabu e Azaghal batem um papo sobre vírus, fungos e bactérias causadores dos mais bizarros DISTÚRBIOS MENTAIS! Neste .

charpy impact test standards|charpy impact test sample dimensions